Car Parts Mold: The Ultimate Guide to Manufacturing, Features, and Selection

Introduction

In the ever-evolving world of automobiles, car parts molds play a crucial role in ensuring high-quality vehicle components. This comprehensive guide will delve into the manufact

uring process, features, advantages, and provide insights on selecting the best car parts mold for your needs.

Man Automobile components mold ufacturing Process

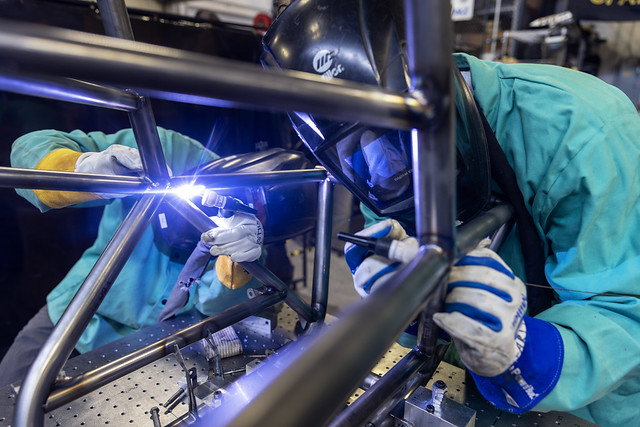

The production of car parts mold involves several steps that require precision engineering and expertise. Vehicle parts molds are created using advanced technologies such as computer-aided design (CAD) software for designing intricate automotiv car parts mold e components. These designs are then translated into physical molds through processes like injection molding or compression molding.

Features and Advantages

Molded car part tooling offers various distinct features that set them apart from traditional manufacturing methods. Firstly, they allow for complex shapes and geometric designs impossible with convention spray nozzle manufacturer al techniques. Additionally, these molds ensure consistent quality across multiple reproductions due to their precise specifications.

Automobile Components Mold is optimized for durability while maintaining lightweight charac nozzle supplier teristics essential in modern vehicles’ performance aspects. Car accessories mold provides seamless integration with other components during assembly due to its meticulous design considerations.

Usage Methods

When using a car parts mold efficiently, it is crucial to follow specific guidelines for maximum productivity. Proper maintenance ensures continued Vehicle parts mold smooth operation by regular cleaning after each use and lubricating moving parts as needed. Furthermore, effectively operating nozzle suppliers assist in achieving optimal results during the molding process by providing uniform material distribution within the mold cavity.

Choosing the Right Product

Selecting an appropriate spray nozzle manufacturer should be based on certain key factors like compatibility wi Molded car part tooling th your existing machinery or equipment setup. Considerations should also include reputation regarding product quality assurance measures implemented by manufacturers when deciding car parts mold on a supplier. Evaluating customer reviews can offer valuable insights into previous users’ experiences and satisfaction levels.

Conclusion

The importance of obtaining high-quality automobile components cannot be overstated in today’s fast-paced automotive industry.Car Part Molds serve as an indispensable tool for achieving consistency, durability and allow car parts mold ing intricate designs. By understanding the manufacturing process, features, advantages, usage methods and selecting reliable suppliers, you can ensure a successful production journey. With this guide in hand, you are now equipped with the knowledge to make informed decisions when venturing into car parts molds selection.

In conclusion, stay updated with th car parts mold e latest advancements in car parts mold technology and unleash the potential of producing cutting-edge automotive components that will drive innovation on our roads!